Improving Concrete Performance: The process of making concrete using innovative admixtures

Concrete is a synthetic material that consists primarily of a mixture of aggregate (such as gravel and sand), water, and cement. Concrete is characterized by its strong properties and durability, making it a popular material used in construction and civil engineering. Improving concrete performance refers to enhancing properties that make concrete more effective and suitable for various building applications. In this article we will talk about the process of making concrete. We will also review innovative additives that improve concrete performance.

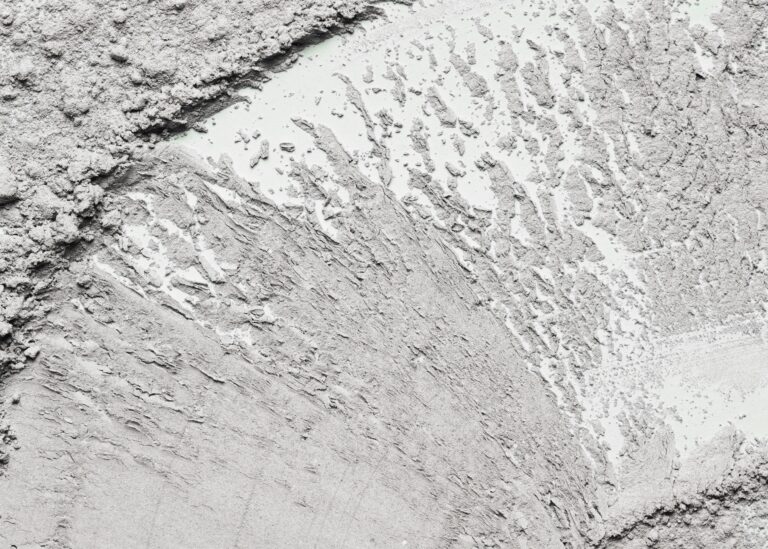

Concrete making process

The process of making concrete consists of creating a homogeneous mixture of basic ingredients. This mixture is poured into the desired shapes and left to harden and hold together. The success in using concrete is attributed to its ability to cohesion and harden, which makes it an ideal material for constructing various buildings and structures.

Concrete has high compressive and tensile strength, making it an ideal material for use in durable structures. It can also be easily formed into different shapes, allowing the construction of diverse architectural and engineering structures.

Concrete is resistant to water, heat, and fire, and is considered a relatively economical building material, making it commonly used in various construction projects.

By using innovative technologies and advanced additives, the performance and properties of concrete can be significantly improved, expanding its use in various engineering and construction fields.

Innovative additives that improve concrete properties

Concrete performance can be improved using a variety of innovative additives that enhance its mechanical and physical properties. These additives make concrete perform stronger, more flexible, more resistant to environmental factors, and more sustainable. This development subsequently improves the performance of concrete and makes it more capable of meeting the needs of different applications better. Among these additions:

1. Anti-corrosion additives: Materials such as ultrafine silica or hard corrosion-resistant metals are added to increase concrete’s resistance to corrosion in environments such as marine environments or those exposed to chemicals.

2. High-performance concrete admixtures: These admixtures include polymers, glass fibers and polymeric fibers that enhance the tensile strength, flexibility and compressive strength of concrete.

3. Additives that enhance heat resistance: These additives include materials such as ceramics and refractory fibers to improve concrete’s resistance to high temperatures.

4. Anti-cracking additives: Materials such as polymers and fiberglass are used to reduce cracks in concrete due to thermal contraction or expansion.

5. Waterproof and anti-leakage additives: They consist of materials that enhance the water absorption threshold and reduce the chances of leakage in concrete structures.

6. Green and sustainable additives: Include materials such as fly ash and recycled materials to reduce the use of non-renewable natural materials and reduce the environmental footprint.

7. Additives that enhance the manufacturing and application process: These include smart concrete forming technology and additives that facilitate more efficient manufacture and application of concrete.

In conclusion, the use of these innovative additives significantly improves the properties of concrete, making it suitable for a variety of applications. These additions also improve the performance and durability of concrete in different conditions.